With a Loring S15iv, seventy kilograms of exceptional green coffeeii, and zero adherence to any steadfast rules,

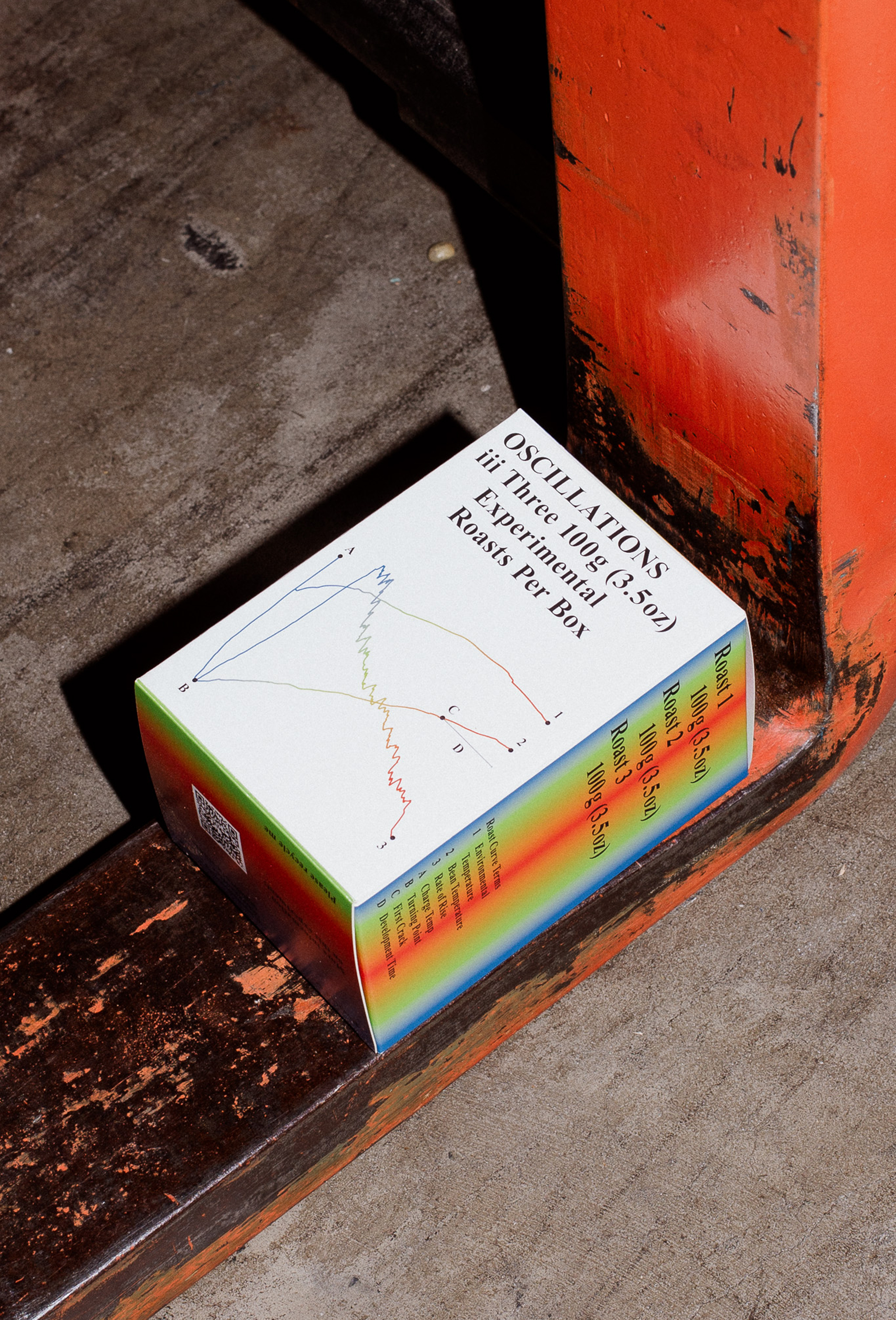

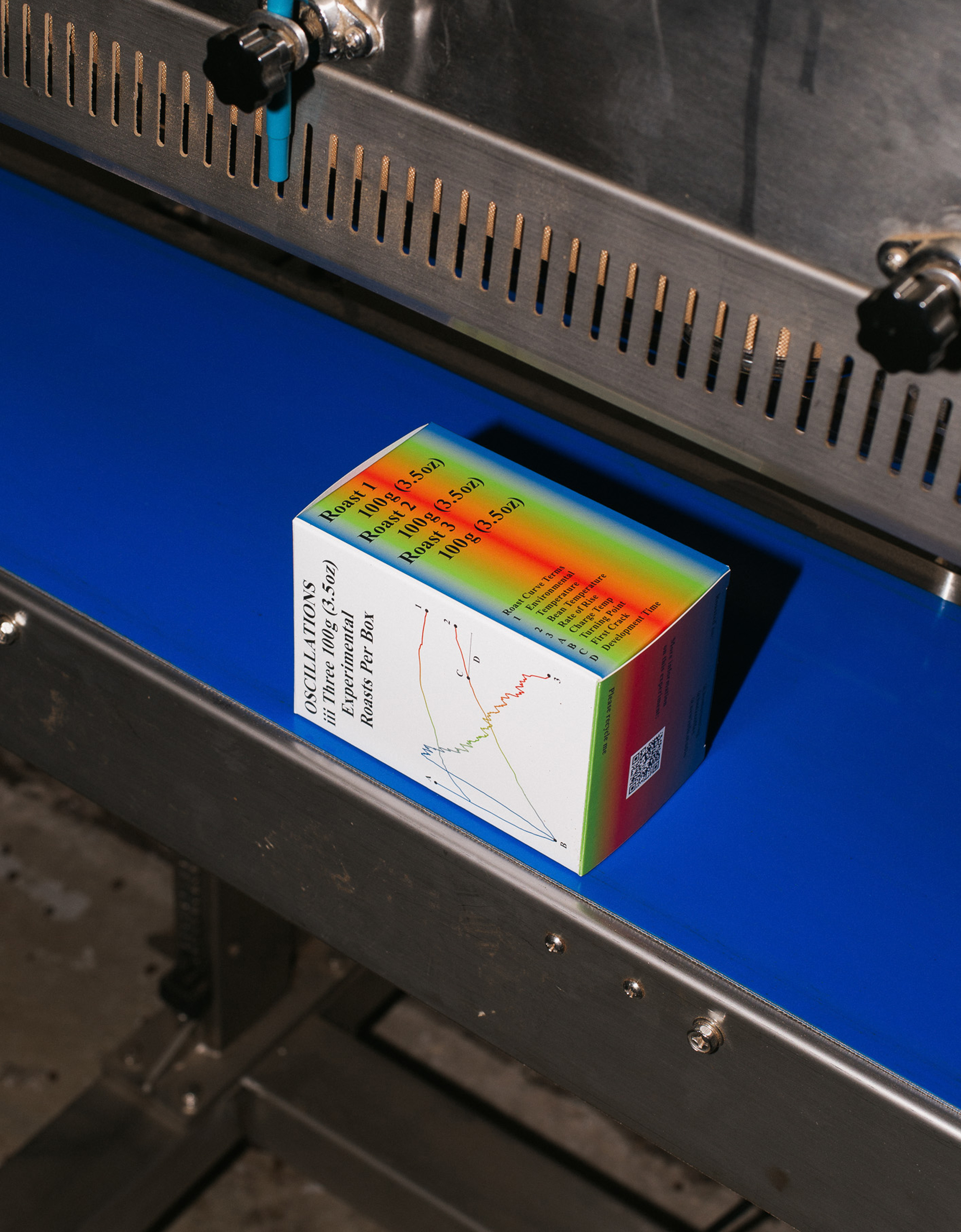

Oscillations was conceived. Guided by taste first, this collaborative endeavor aims to demonstrate unique approaches to roasting coffee on a Loring system. We invite you to explore the plethora of information we’re sharing here, including specific roast curves and dataiii, the story behind the beanii we roasted, and background on our teamvi.

An experimental roasting collaboration with Homecoming* Botz Coffee† and New Information‡

i

ABSTRACT

ii

BEAN

We selected Nestor Lasso’s Caturra Chiroso lot for its exceptional innate qualities and terroir, making this raw bean a perfect subject for this experimental endeavor. The beautiful Caturra Chiroso variety comes from Nestor Lasso’s farm El Diviso

, located in the Huila region of Colombia. Nestor and his brother Adrian took over the family farm founded by their grandfather, and decided to pursue specialty coffee production, with the ambition of having their coffees reach a global audience.

Farm

El Diviso

Alt

1850 MASL

Loc

Huila, Pitalito

Variety

Caturra Chiroso

Process

Anaerobic Washed

—

Floating process in order to select the best cherries only (fully ripe).

—

16 hour oxidation in cherry between 22 and 30 degrees Celsius.

—

Anaerobic fermentation in plastic cans for 38 hours at 16-18 Celsius.

—

The coffee is moved to open fermentation tanks for 6 hours where the leachates are collected so they can be used further on.

—

The coffee is pulped.

—

Oxidation process in mucilage for 6 hours.

—

Water and the leachates collected in step 4 are added to the coffee to begin a 24 hour submerged fermentation at 32 degrees Celsius. The mix is occasionally stirred so the mix is homogenous.

—

Thermal shock: the coffee is washed with water at 65-70 Celsius to finalize the fermentation phase.

—

The coffee is moved to parabolic drying systems for 18-24 days until 11% moisture is reached, where the maximum temperature is 30 degrees Celsius.

iii

ROASTS

When tasting coffees roasted on Loring machines utilizing more conventional techniques, we found ourselves questioning the untapped potential of the system, and brainstorming new approaches. Together, we ventured out on a roasting exploration to gain a better understanding of the Loring, to answer lingering questions, and create new ones.

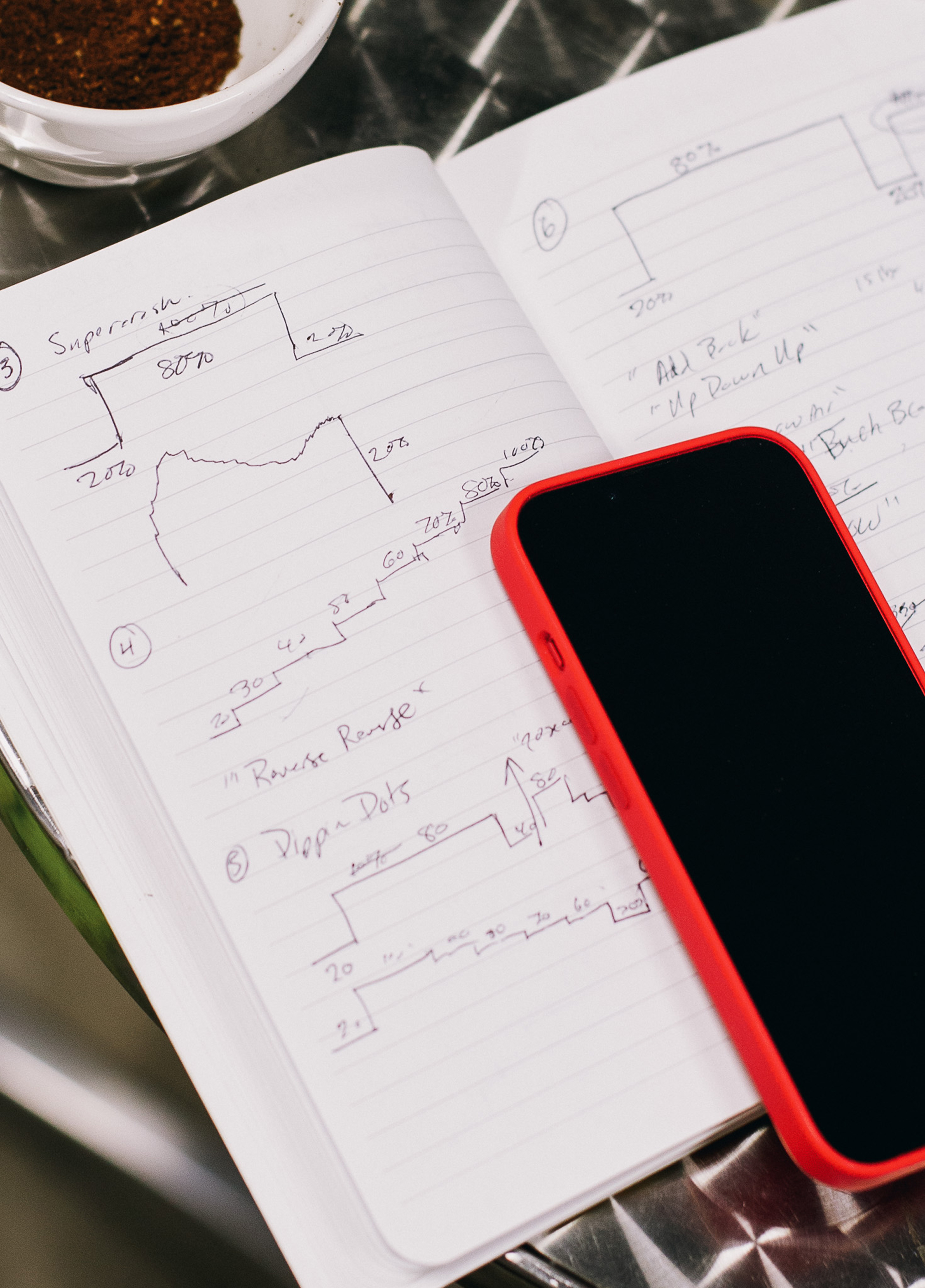

Before roasting, we brainstormed different roasting techniques from our own experiences, as well as information available in the roasting community at large. After cupping two blind tables of coffees representing different roasting approaches, we found seven compelling renditions. These renditions represent techniques we believe created distinctly enjoyable variations of the same coffee.

We hope you experience the unique nuances of three different roasts contained in this Oscillations set. The roast methodologies, their motivations, flavors, and cup characteristics are all provided below.

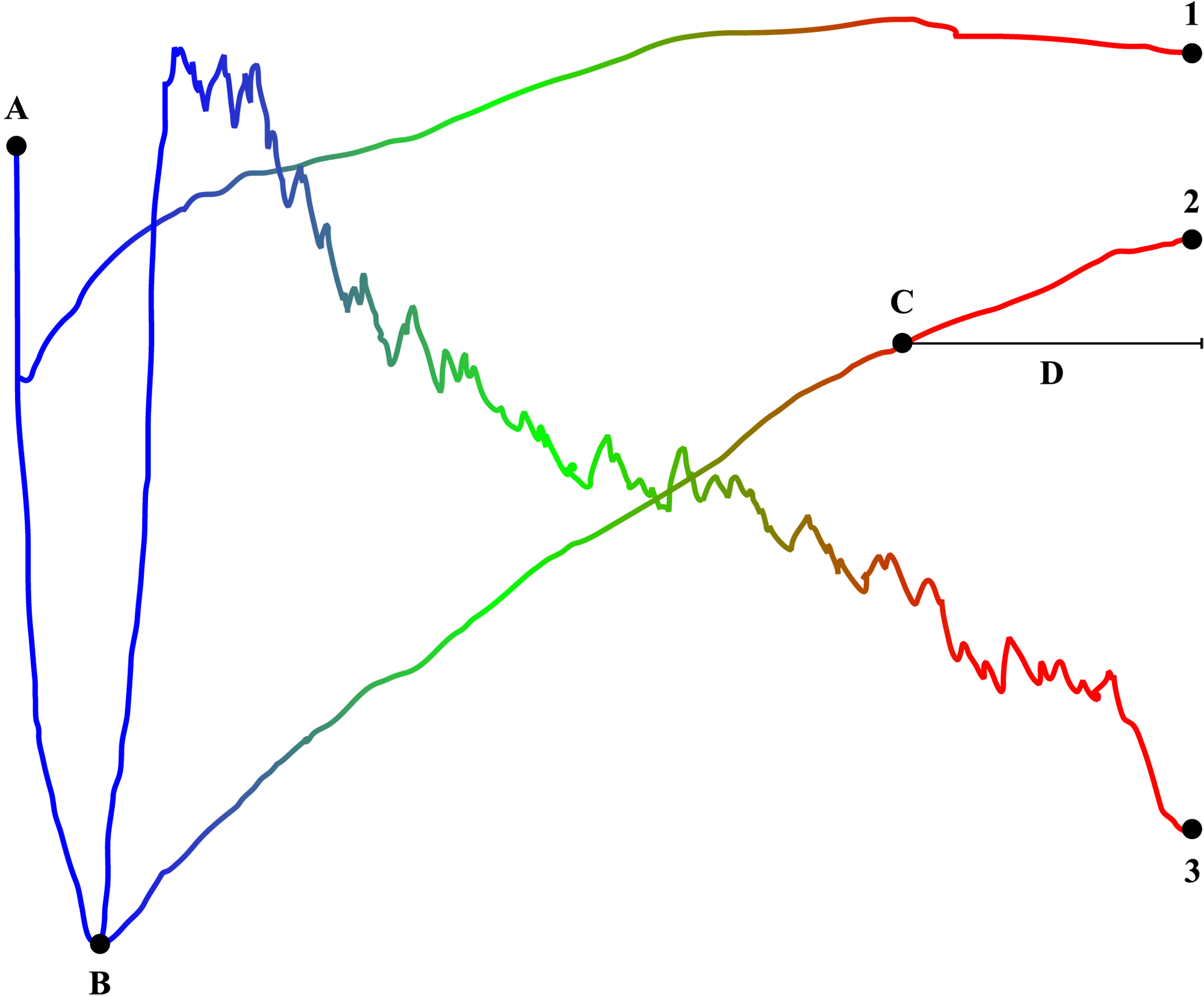

Roast Curve Terms

1

Environmental Temperature

Temperature inside the roaster drum.

2

Bean Temperature

Temperature of green coffee while being roasted.

3

Rate of Rise (RoR)

The number of degrees per minute the temperature of the beans increases during a roast.

A

Charge Temp

The temperature reading of the drum when the beans are dropped.

B

Turning Point

When the bean probe and the green coffee reach an equilibrium in the system, creating a turning point on the curve.

C

First Crack

The initial cracking sound coffee makes around 393°F, (based on our own Loring experience). Marks one of the most important segments of the roasting process.

D

Development Time (the period after the onset of the first crack until the end of the roast)

Gas X

The value or power of the gas setting. (for example gas 20). The highest value of gas on a Loring system is 100. The lowest is 20.

Cupping Protocols

All coffees were cupped with a 1:17 ratio utilizing Third Wave Water Classic (150 ppm). We recommend using a grinder setting between 400 – 500 microns. Crusts were broken at 4:00 minutes by passing through the bottom of the bowl five times. The same cupper broke all the crusts for continuity purposes. Our team started tasting at 11:00 minutes.

Roast Name

(Select for More Info)

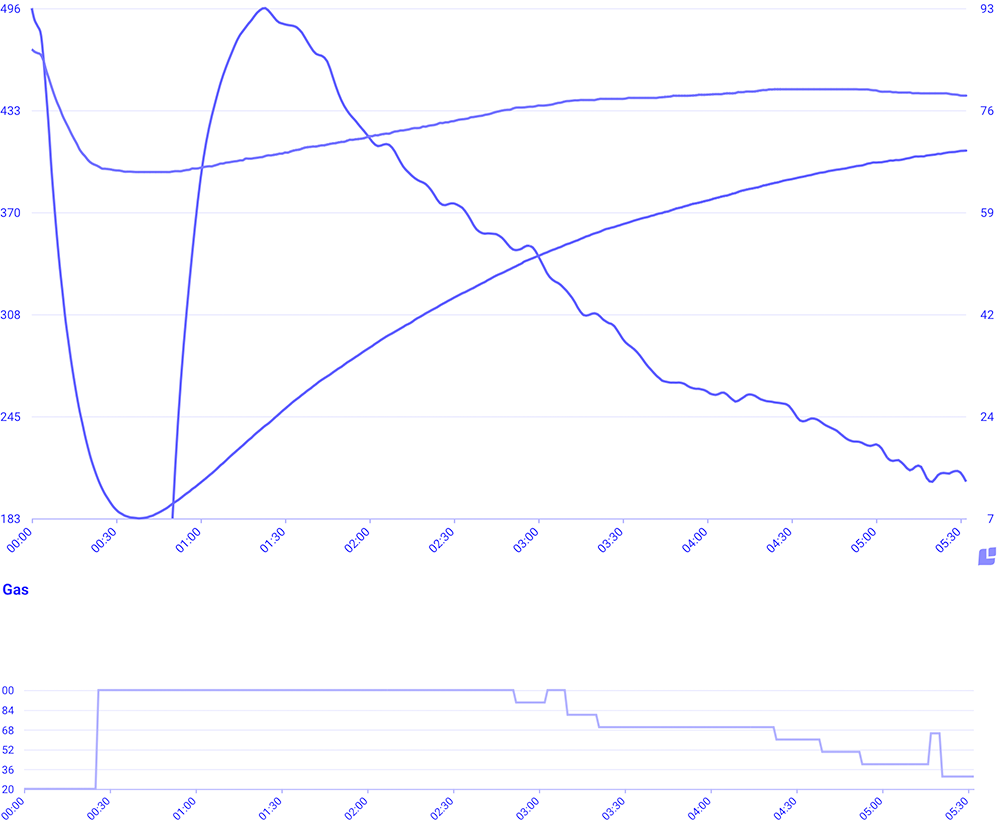

We blasted this 14lb batch. We started with a high charge temp (490°F on the bean probe) and then immediately hit the coffee with full gas. The gas pattern for this coffee was pretty traditional (stepping down on the gas quickly), but at just over 5 minutes, we felt excited to taste how an extremely fast roast would cup on the Loring system.

In his experience, anytime Danny† had ever roasted a coffee with such extreme gas on a drum roaster, he mentioned that he always found the cup character to be harsher with carbon tones. With such a fast roast, he was expecting this coffee to have a more carbon-like character with some underdevelopment.

First Crack

04:36

Duration

05:32

Dev. Time

00:56

Dev. Time Ratio

16.9%

Start Temp

495.5°F

End Temp

408.2°F

On the table, the team found this coffee to be absent any roasty

notes or harsher tones. Instead we experienced really delicate and clear tropical fruit notes. In 3-4 weeks, we predict that this roast may open up further to offer more intensity in the cup.

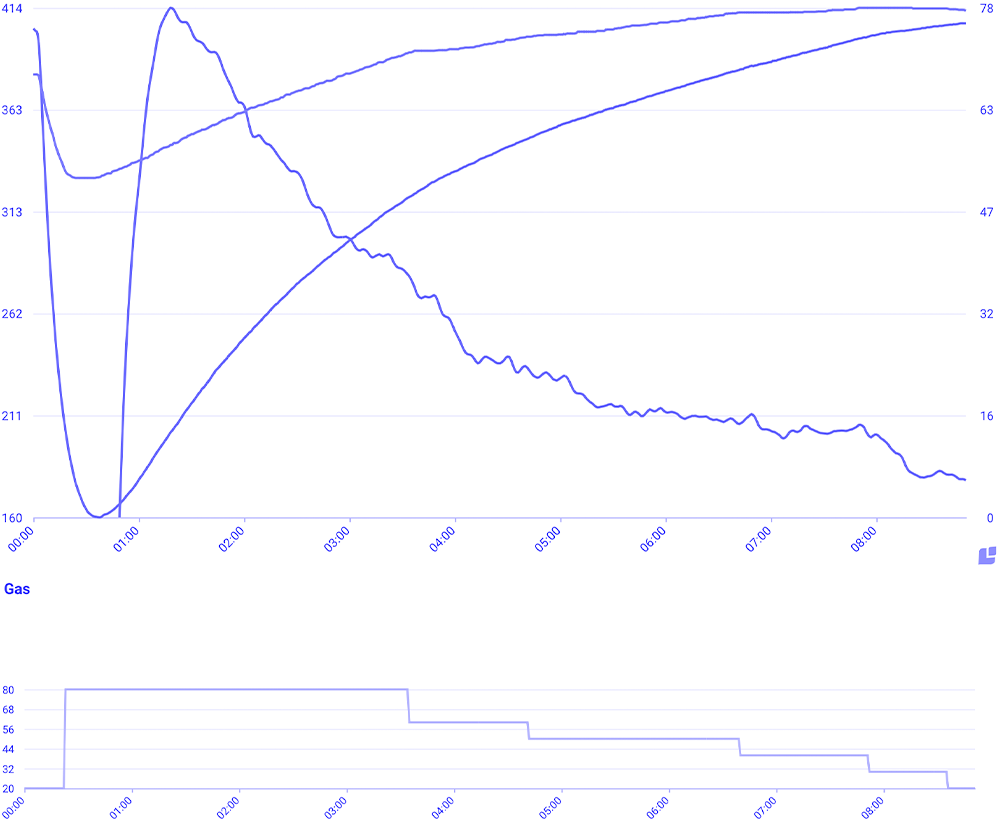

Roast Curves & Gas/Power Time

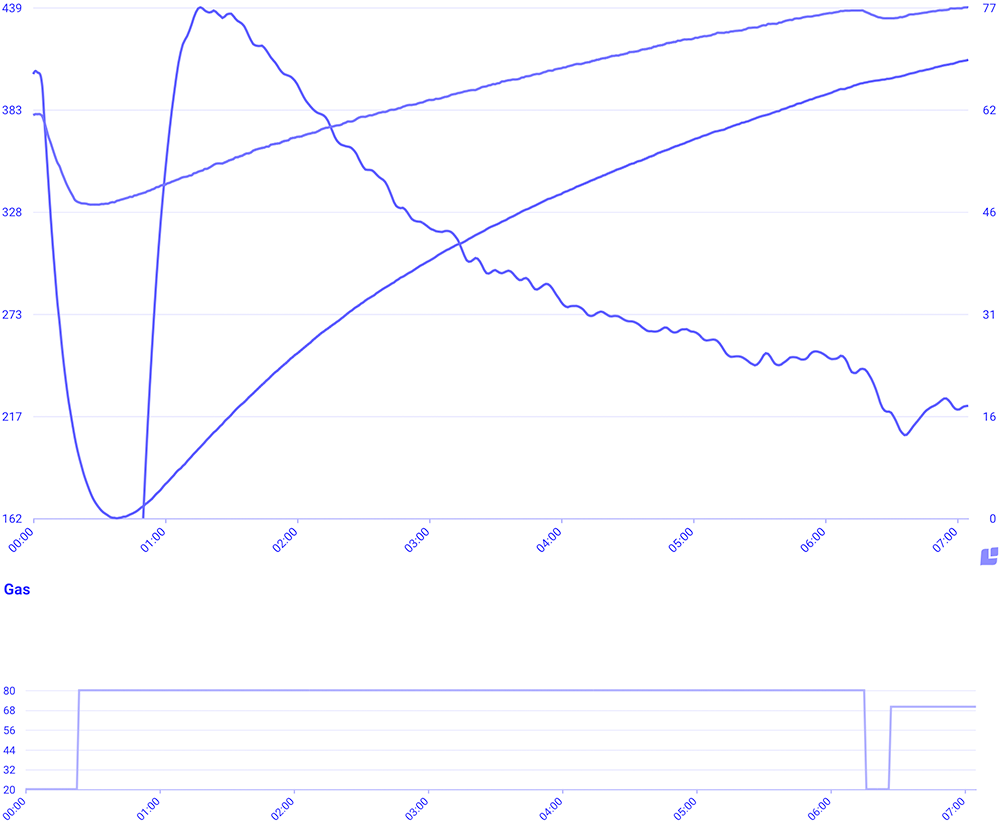

In our experience, Loring systems are much more reactive to changes in gas applications. Without a drum being heated directly by burners, we wondered if we could test a rule that Danny† and Devin§ were generally in agreement with – avoid adding gas back while roasting on drum systems.

Both had seen curves of aesthetically pleasing RoRs (steadily declining with a linear shape) with gas added back later in the roast to mitigate crashes (a sudden vertical drop in the RoR), only to find that the coffees suffered on the cupping table. They had less nuance with a harsher carbon-like character. Would this same concept apply on a Loring?

For this methodology, when we approached first crack, we cut the gas drastically (gas 20) and then added it back quickly at a high setting (gas 70) for a fast finish to the roast.

First Crack

07:12

Duration

08:27

Dev. Time

01:15

Dev. Time Ratio

14.8%

Start Temp

403°F

End Temp

405.4°F

Cupping Notes

We tasted a blood orange citric acidity with a bit of tropical and stone fruit character. Despite adding gas back at a critical stage of the roast, cuppers did not find this coffee to portray a roasty

or harsher character.

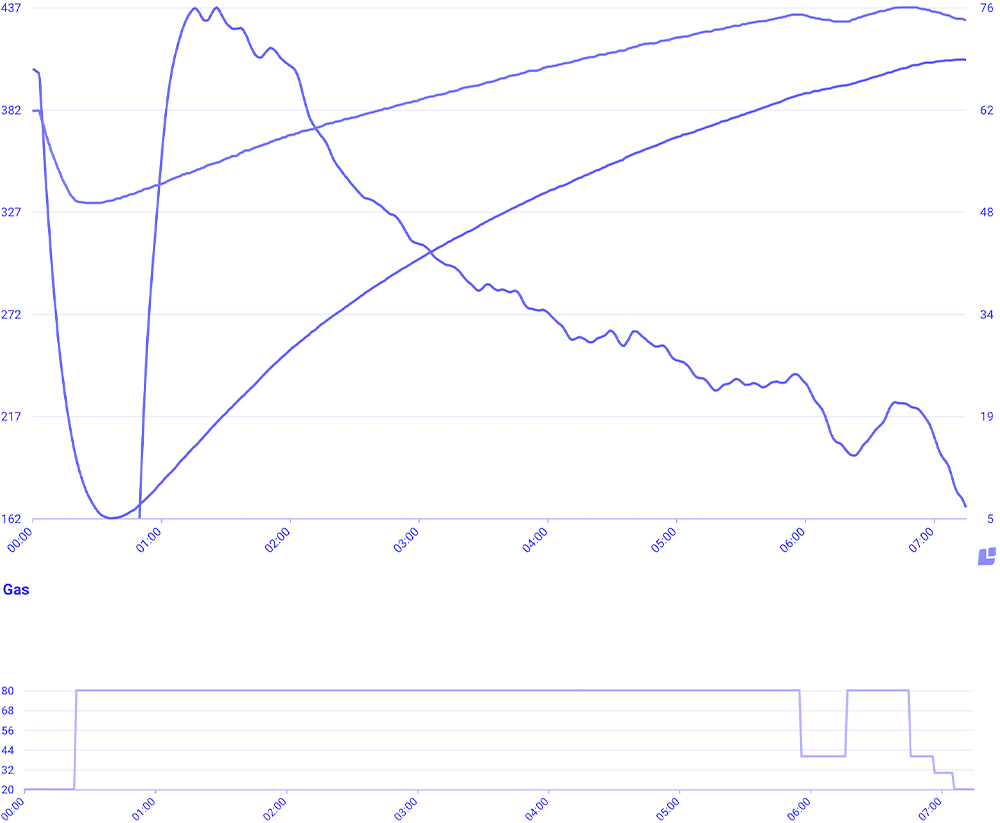

Roast Curves & Gas/Power Time

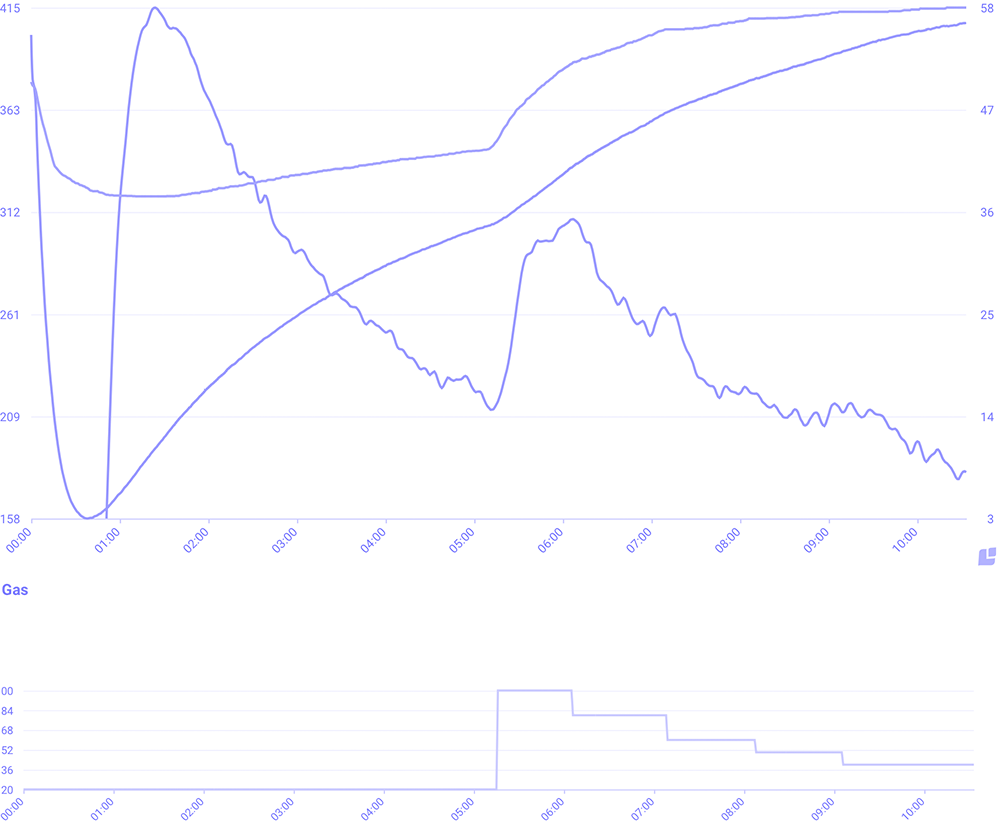

To soak

a coffee is to initially provide the roasting system with minimal gas and energy to allow the green

coffee to soak

up the initial energy in the system. With traditional drum systems, some would argue that this

provides the coffee a softer and more nuanced character because it mitigates initially damaging the coffee from too

hot of a drum surface.

To our own knowledge, the fixed drum and paddles of a Loring do not get very hot, but we

wanted to examine the soaking principle in an extreme scenario to see if there was something more to initially

providing less energy to the coffee in a highly convective environment. We decided to soak

this batch with gas

20 for a drastic 5 minutes before ramping up the gas intensely and stepping it down.

Truth be told, all cuppers found this coffee to be rather memorable on the table. On two blind tables, the coffee was easily recognizable for all cuppers present. It provided the ripest tasting sensations with a lingering and weighty fruit character.

Some further observations and roaster thoughts:

Approximately half of the roast was at gas 20. Since airflow is directly tied to the burner settings in Loring systems, it’s arguable that half of this roast was executed in the lowest possible airflow environment.

After the

initial massive soak,

the RoR for the rest of the roast is rather steadily declining. Some of our cuppers found

the steadily-declining RoRs to have some livelier/zestier characteristics on the cupping table.

The

Supersoaker

methodology, we believe based on our own sensory analysis, deserves some attention. We’re currently

testing this methodology on other coffees to see if it provides similar results.

First Crack

09:14

Duration

10:33

Dev. Time

01:23

Dev. Time Ratio

13.1%

Start Temp

400.8°F

End Temp

406.9°F

Cupping Notes

We found this coffee to offer weighty, saturated, and ripe stone fruits, like peach and mangoes with a velvety chocolate cake like finish. There was a shared emphasis on the fullness, balance, and coherency of this rendition.

Roast Curves & Gas/Power Time

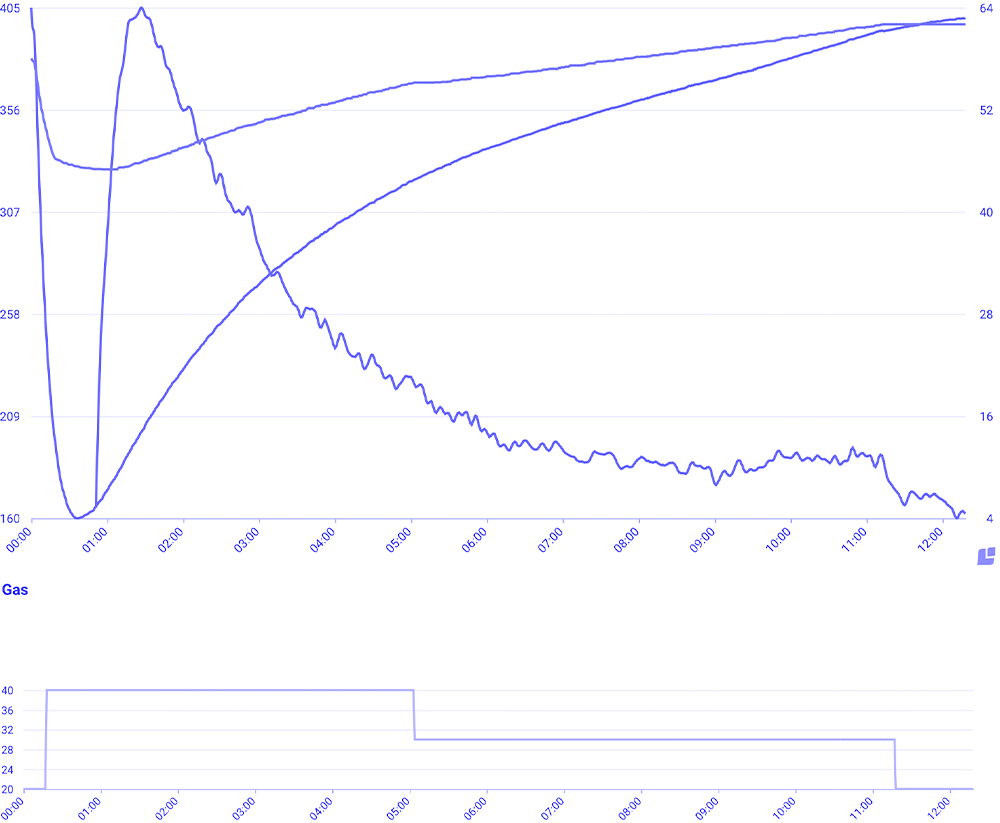

Loring’s can roast a coffee extremely fast. Since we blasted a roast with extreme gas in just over five minutes, we wanted to see what would happen with a lengthier roast and a softer gas application.

With a peak gas setting of 40, we were able to stretch this roast to 12 minutes. The RoR sags significantly in the beginning of the roast and flat lines midway through.

First Crack

11:03

Duration

12:18

Dev. Time

01:15

Dev. Time Ratio

10.2%

Start Temp

405.3°F

End Temp

400.3°F

Cupping Notes

When tasting, we found this coffee to offer a softer peach character with a deeper sweetness and pleasant balance.

Roast Curves & Gas/Power Time

Since Danny and Devin have primarily roasted on drum roasters, we thought it might be eye-opening to see what flavors and cup characteristics we’d find with a traditional drum roasting gas pattern.

We provided ample gas up front while stepping it down steadily before and after first crack.

First Crack

07:23

Duration

08:51

Dev. Time

01:28

Dev. Time Ratio

16.6%

Start Temp

403.8°F

End Temp

406.4°F

Cupping Notes

As a group, we found this roast to offer pleasant cutting/zippy acid. One cupper found the coffee to offer more of a melon character (watermelon), while another found the coffee to have a clean white peach character and lemongrass acidity.

Roast Curves & Gas/Power Time

This technique utilized a gas dip methodology. We also had another roast that we tried to purposefully crash very hard, so we tried to time the dip based on that roast (40 seconds away from the start of the crash with a dip that’s 50% of the gas setting before the dip. We tried to time our dip for 20 seconds). After adding the gas back, we quickly stepped the gas down to finish the roast.

First Crack

06:08

Duration

07:15

Dev. Time

01:07

Dev. Time Ratio

15.4%

Start Temp

403.5°F

End Temp

408.9°F

Cupping Notes

Our group collectively found this coffee to offer a subtle sweetness and juiciness, akin to artificial peach, soft

cherries and clementine. It is important to note that the RoR3 did dip down drastically. It would be

interesting to to dip

another roast to observe how it cups in reference to a more linear RoR.

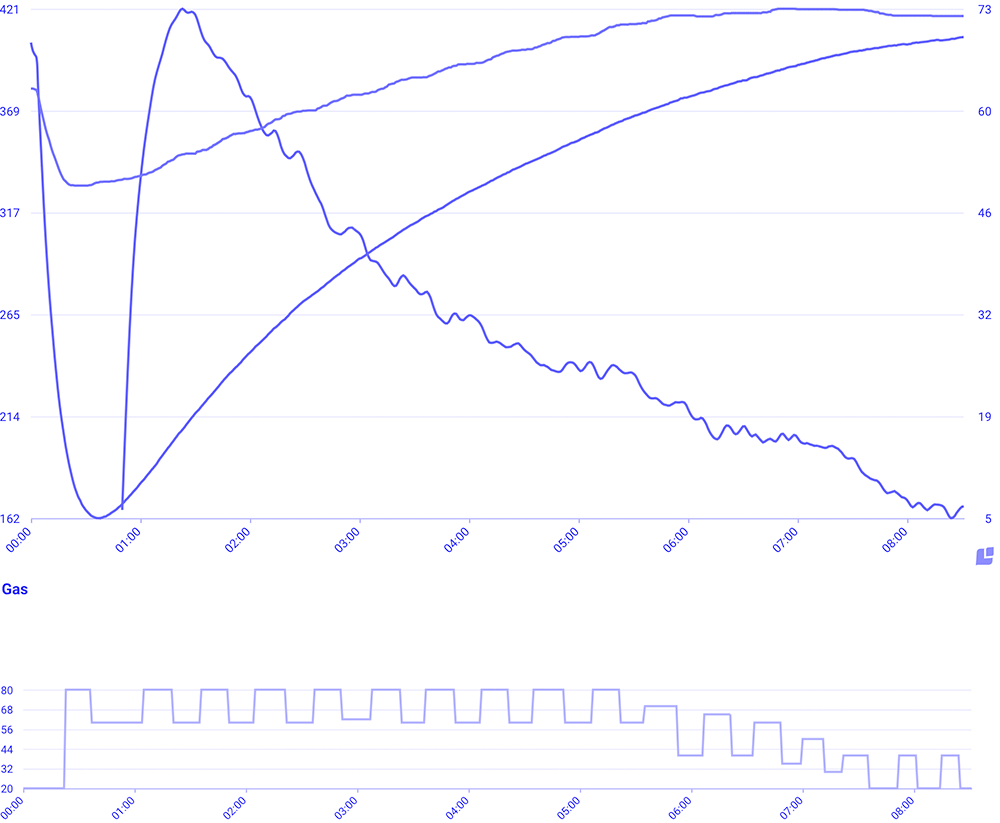

Roast Curves & Gas/Power Time

This methodology could be a roaster operator’s greatest nightmare (haha), but Devin and Danny were up for a challenge. How could we, after all, have a project named Oscillations without oscillating one of the roasts!

The main goal of this roast was to oscillate the gas up and down at a controlled rate, meaning frequent gas changes with precise timing. We started with higher gas oscillation settings and stepped down to lower oscillation settings to taper off energy in the system.

The inspiration behind this methodology was partly inspired by some Loring automation roasts. For some automated Loring roasts, the gas fluctuates rather drastically down and up. We chose to explore a more controlled scenario where we tried to execute a roast with a steadily declining RoR with less drastic fluctuations. Collectively, we were rather pleased with the RoR shape of this roast and were excited to see if it would perform.

First Crack

07:01

Duration

08:31

Dev. Time

01:30

Dev. Time Ratio

17.6%

Start Temp

404°F

End Temp

406.8°F

Cupping Notes

In comparison to some of the other roasts, we found this coffee to have a riper and richer character. We tasted heavy stone fruits backed by a rich chocolate sensation. We also found this rendition of the coffee to be more developed than the other batches.

Roast Curves & Gas/Power Time

Gas Pyramid

This roast’s gas pattern looks like a pyramid instead of the more traditional downwards staircase. We initially stepped the gas up to a peak setting and then finished our roast by stepping the gas downwards. Both of the roaster operators were excited after seeing the shape of this roast’s RoR.

Cuppers found this coffee to offer a slight oatiness, flatter character, and softness of flavors. We’d like to highlight that our cupping experience could be due to a roast development issue and not this given methodology.

Reverse

For this strategy, we decided to roast in reverse, meaning instead of starting with an initial high gas setting and stepping down, we started with a low setting and stepped up the gas to its highest possible setting near the end of the roast.

Collectively we found this coffee to be the most underdeveloped of all of our renditions. We tasted lemongrass acidity and green-like florals. The finish of this coffee was muted and quick. If given another chance, we’d aim for more adequate development to try and decipher the effects of reverse gas application.

Super Crash

RoR crashes (sudden vertical drop in RoR) are quite possibly one of the most controversial topics in the realm of coffee roasting. Some argue that a crash can rob coffee of sweetness and vibrancy, while others might argue that it can provide a roast balance or even enhance the sweetness of a given coffee. Naturally, we decided to try and make a coffee crash super hard to solve the crash debate.

We provided this coffee with ample gas upfront to

plateau

the RoR (a moment near first crack when the RoR stops declining and beings to flat line to create a

plateau like shape). When we felt like we had provided the coffee with sufficient energy to create the plateau

,

we drastically reduced the gas to create our own super crash. As we watched the RoR fall, we felt like we had achieved

our goal.

Collectively our team found this coffee to be intensely flat with mild and soft fruit tones. In comparison to other renditions, the acidity seemed lackluster. While we aren’t ready to say with full confidence that we know how crashes affect a given coffee’s flavor, in this scenario we did find a correlation with the super crash and a muted cup character.

iv

LORING S15

All the coffees for Oscillations were roasted on a Loring S15 (15kg) at Shared Roasting. Unlike traditional drum roasters that utilize a combination of conduction and convection to roast, Loring systems are almost exclusively convective. We set out to explore the possibilities and limits of this system as it relates to traditional drum roasters.

v

DOCUMENTATION

vi

TEAM

*

Homecoming

home-coming.com†

Botz Coffee

botz-coffee.com‡

New Information

newinfo.studio§

Devin Eiring

¶

Cold Rice

cold-rice.info#

Special Thanks